The market drivers of conformal coatings in electronics are influenced by various factors shaping the demand for protective coatings in different industry segments. Here are some key market drivers:

Miniaturization and Component Density: As electronic devices become smaller and more compact, there's a greater need for conformal coatings in electronic market to protect delicate components from environmental factors such as moisture, dust, and chemicals. The trend towards miniaturization increases the surface area of electronic assemblies, necessitating efficient coating solutions to ensure reliable performance and longevity.

Harsh Operating Environments: Electronics used in automotive, aerospace, industrial, and outdoor applications are often exposed to harsh operating environments characterized by temperature extremes, vibration, humidity, and chemical exposure. Conformal coatings provide a barrier against these environmental stresses, preventing corrosion, electrical short circuits, and premature failure of electronic components.

Reliability and Longevity Requirements: Manufacturers and end-users alike demand electronics with extended operational lifetimes and minimal maintenance requirements. Conformal coatings play a critical role in enhancing the reliability and longevity of electronic assemblies by protecting them from degradation and ensuring consistent performance over time.

Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2023-2032 – By Product Type, Application, End-user, and Region: (North America, Europe, Asia Pacific, Latin America and Middle East and Africa): https://www.persistencemarketresearch.com/market-research/conformal-coatings-in-electronics-market.asp

Regulatory Compliance and Standards: Compliance with regulatory requirements and industry standards regarding safety, reliability, and environmental impact drives the adoption of conformal coatings in electronics manufacturing. Regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) influence the selection of coating materials and formulations to ensure they meet stringent environmental and health standards.

Emerging Applications and Technologies: Advancements in technology, such as the Internet of Things (IoT), wearable electronics, autonomous vehicles, and 5G telecommunications, create new opportunities for the deployment of electronic devices in diverse environments and applications. Conformal coatings enable the reliable operation of electronics in these emerging markets by protecting them from environmental hazards and ensuring optimal performance.

Increased Investment in R&D: Continued investment in research and development by coating manufacturers and electronics OEMs leads to the development of innovative coating formulations, application techniques, and performance enhancements. R&D efforts focus on improving the properties of conformal coatings, such as adhesion, flexibility, thermal conductivity, and self-healing capabilities, to meet evolving industry requirements and customer needs.

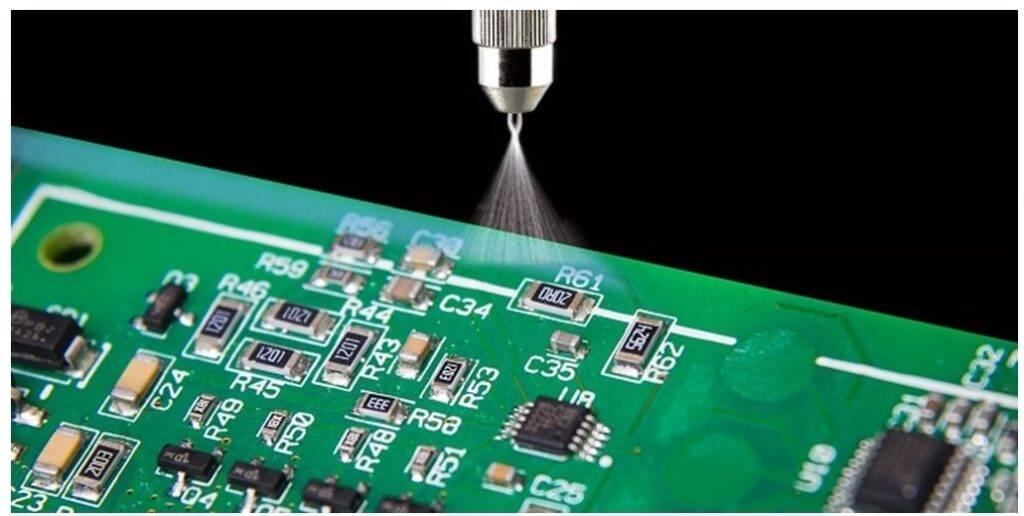

Cost Reduction and Efficiency Improvements: Manufacturers seek cost-effective coating solutions that offer efficient application processes, minimal material waste, and reduced labor costs. Advances in application technologies, such as selective coating systems, automated spraying, and inline curing methods, contribute to improved efficiency and productivity in electronics manufacturing while ensuring consistent coating quality.

Globalization and Supply Chain Dynamics: The globalization of electronics manufacturing and supply chains drives the demand for conformal coatings that can withstand international shipping, storage, and assembly processes. Coating suppliers must provide reliable products and support services across regions to meet the needs of multinational OEMs and contract manufacturers.

These market drivers underscore the importance of conformal coatings in protecting electronic devices and assemblies, supporting industry growth, and enabling technological innovation across various sectors.

About Persistence Market Research:

Business intelligence is the foundation of every business model employed by Persistence Market Research. Multi-dimensional sources are being put to work, which include big data, customer experience analytics, and real-time data collection. Thus, working on “micros” by Persistence Market Research helps companies overcome their “macro” business challenges.

Persistence Market Research is always way ahead of its time. In other words, it tables market solutions by stepping into the companies’/clients’ shoes much before they themselves have a sneak pick into the market. The pro-active approach followed by experts at Persistence Market Research helps companies/clients lay their hands on techno-commercial insights beforehand, so that the subsequent course of action could be simplified on their part.

Contact

Persistence Market Research

Teerth Techno space, Unit B-704

Survey Number - 103, Baner

Mumbai Bangalore Highway

Pune 411045 India

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com